Panzerhand® M2

A protective, top quality cut resistant glove. The glove is a technical innovation of the model successfully manufactured since 1983, based on patent technology (invention) while applying modern materials and procedures as well. Due to the new technologies, the glove is more resistant and pleasant to wear. In order to increase the protection level, the hem is extended by 4 cm.

The biggest area of applications is in jobs with a high risk of hand injury caused by a cutting edge, namely in the foodstuff industry e.g. chopping – the glove is a cheaper and more comfortable alternative to looped gloves. It is useful in other industrial branches as well (for example, sheet metal manufacture etc.).

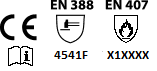

The comparison table of values according to EN 388:2016

| Abrasion resistance: | class 4 (max. 4) |

| Cut resistence Coupe test: | class 5 (max. 5) |

| Tear resistance: | class 4 (max. 4) |

| Puncture resistance: | class 1 (max. 4) |

| Cut resistence TDM test: | class F (max. F) |

The comparison table of values according to EN 407:2004

| Contact heat: | class 1 (max. 4) |

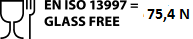

The glove is in conformity with EN ISO 13997 as for surface cut, achieving excellent results of 75,4 N (Newton). In comparison, 22 Newton corresponds to class 5 according to EN 388:2016.

The gloves comply with the requirements of regulation (EC) No 1935/2004 of the european parliament and of the council on materials and articles intended to come into contact with food. This is documented by a specific certificate.

The gloves do not contain any glass fibres, which break to pieces during work and can remain in the food being handled!

Variant Silvernite

An anti-bacterial version of Panzerhand M2 gloves containing nanofibre enriched with silver ions. The silver has permanent antibacterial effects. According to EN ISO 20743, the gloves are classified as „Red Level“ i.e. the antibacterial effect resists 50 washing cycles. The treatment is efficient for food processing.

Panzerhand® M2

A protective, top quality cut resistant glove. The glove is a technical innovation of the model successfully manufactured since 1983, based on patent technology (invention) while applying modern materials and procedures as well. Due to the new technologies, the glove is more resistant and pleasant to wear. In order to increase the protection level, the hem is extended by 4 cm.

The biggest area of applications is in jobs with a high risk of hand injury caused by a cutting edge, namely in the foodstuff industry e.g. chopping – the glove is a cheaper and more comfortable alternative to looped gloves. It is useful in other industrial branches as well (for example, sheet metal manufacture etc.).

The comparison table of values according to EN 388:2016

| Abrasion resistance: | class 4 (max. 4) |

| Cut resistence Coupe test: | class 5 (max. 5) |

| Tear resistance: | class 4 (max. 4) |

| Puncture resistance: | class 1 (max. 4) |

| Cut resistence TDM test: | class F (max. F) |

The comparison table of values according to EN 407:2004

| Contact heat: | class 1 (max. 4) |

The glove is in conformity with EN ISO 13997 as for surface cut, achieving excellent results of 75,4 N (Newton). In comparison, 22 Newton corresponds to class 5 according to EN 388:2016.

The gloves comply with the requirements of regulation (EC) No 1935/2004 of the european parliament and of the council on materials and articles intended to come into contact with food. This is documented by a specific certificate.

The gloves do not contain any glass fibres, which break to pieces during work and can remain in the food being handled!

Variant Silvernite

An anti-bacterial version of Panzerhand M2 gloves containing nanofibre enriched with silver ions. The silver has permanent antibacterial effects. According to EN ISO 20743, the gloves are classified as „Red Level“ i.e. the antibacterial effect resists 50 washing cycles. The treatment is efficient for food processing.