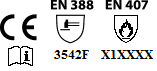

Certification:

Product variants:

Size:

The sizes are differentiated by the colour of the border:

antiCUT® MAX 5

This glove is created from a special composite yarn Brinix® MAX5 with steel, polyethylene, polyamide and other ressistant fibres. Retaining fine glove features (feeling in fingers) this glove reaches outstanding values of both abrasion and cut resistence according to EN 388. This glove cannot be practically compared with the Aramid one – a similar glove would be produced very hardly.

The gloves do not contain any glass fibres, which break to pieces during work!

These gloves are particularly suitable for assembly work, handling sheet metal, handling construction materials, etc., where there is a risk of cuts, scratches, and abrasion. Due to its construction, the glove has an excellent grip ability.

Gloves are offered in different versions:

GRIP – gloves are fitted with non-slip pvc dots.

SKIN – split cow‘s leather is sewn on the palm; these gloves are primarily used for handling oily sheet metal, on assembly lines, in the construction industry for handling rough materials, in the repair of agricultural machinery, etc. The glove is even resistant against punctures in the reinforced split leather area.

SLEEVE – version of a sleeve which mainly protects the forearm against the risks of cuts, scratches and abrasions. We can make the length according to customer requirements, or you can choose from standard manufactured lengths of 25 cm, 35 cm, 45 cm, and 55 cm. You can select the version with or without a thumb hole. Velcro can also be added to the sleeve for better comfort.

The comparison table of values according to EN 388:2016

| Abrasion resistance: | class 3 (max. 4) |

| Cut resistence Coupe test: | class 5 (max. 5) |

| Tear resistance: | class 4 (max. 4) |

| Puncture resistance: | class 2 (max. 4) |

| Cut resistence TDM test: | class F (max. F) |

The comparison table of values according to EN 407:2004

| Contact heat: | class 1 (max. 4) |

antiCUT® MAX 5

This glove is created from a special composite yarn Brinix® MAX5 with steel, polyethylene, polyamide and other ressistant fibres. Retaining fine glove features (feeling in fingers) this glove reaches outstanding values of both abrasion and cut resistence according to EN 388. This glove cannot be practically compared with the Aramid one – a similar glove would be produced very hardly.

The gloves do not contain any glass fibres, which break to pieces during work!

These gloves are particularly suitable for assembly work, handling sheet metal, handling construction materials, etc., where there is a risk of cuts, scratches, and abrasion. Due to its construction, the glove has an excellent grip ability.

Gloves are offered in different versions:

GRIP – gloves are fitted with non-slip pvc dots.

SKIN – split cow‘s leather is sewn on the palm; these gloves are primarily used for handling oily sheet metal, on assembly lines, in the construction industry for handling rough materials, in the repair of agricultural machinery, etc. The glove is even resistant against punctures in the reinforced split leather area.

SLEEVE – version of a sleeve which mainly protects the forearm against the risks of cuts, scratches and abrasions. We can make the length according to customer requirements, or you can choose from standard manufactured lengths of 25 cm, 35 cm, 45 cm, and 55 cm. You can select the version with or without a thumb hole. Velcro can also be added to the sleeve for better comfort.

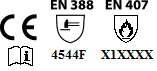

The comparison table of values according to EN 388:2016

| Abrasion resistance: | class 3 (max. 4) |

| Cut resistence Coupe test: | class 5 (max. 5) |

| Tear resistance: | class 4 (max. 4) |

| Puncture resistance: | class 2 (max. 4) |

| Cut resistence TDM test: | class F (max. F) |

The comparison table of values according to EN 407:2004

| Contact heat: | class 1 (max. 4) |